Introduction

Fiberglass damage comes in all shapes, sizes, and types. The depth and size of the damage determines what method you should use to repair. For shallow voids, dents, and crazing, you can use a fairing compound. For deeper gouges and holes, you would do a proper FRP repair using mixed resin, fillers, and reinforcement fabric. The TotalBoat 5:1 Traditional Epoxy system forms high-strength bonds with fiberglass, wood, reinforcement fabrics, and metals. Combine it with the proper fillers and it creates an excellent thickened adhesive, fairing compound, or filleting material.

Tools

Video Overview

-

-

Protect the surrounding area: Use poly sheeting and masking tape to protect the areas adjacent to the area you’re going to repair.

-

Clean the surface: Dampen a clean cotton rag with acetone and wipe the surface of the repair area to remove contamination and loose debris.

-

Sand and grind: Use 36-80 grit sandpaper (depending in the severity of the damage) and an appropriate grinder to remove any loose gelcoat or fiberglass debris from the damaged area. For rounded edges, use an appropriate bit.

-

Sand a little beyond the border of the damaged area to provide maximum adhesion for the repair.

-

For damage that goes all the way through (where fabric repairs are necessary), grind out the area at 5:1 or greater width to the depth of the repair.

-

Clean the repair area thoroughly:

-

Vacuum the surface to remove sanding/grinding residue.

-

Remove any remaining surface residue or contamination by wiping the repair area with a clean rag dampened with acetone. Allow the solvent to dry completely.

-

-

-

To ensure that the repair patch has maximum adhesion, you will mix and brush on a thin layer of mixed, thickened epoxy.

-

To create this mixture, combine TotalBoat 5:1 Epoxy Resin & 5:1 Slow Hardener in a clean, plastic mixing cup. Always use the correct ratio of 5 parts epoxy resin to 1 part hardener (by volume) and mix thoroughly.

-

Next, add a little bit of TotalBoat Silica Thickener, and stir until the mixture is a ketchup consistency.

-

-

-

You will use mixed, unthickened epoxy (no filler) to wet out small pieces of fiberglass cloth to patch the repair area.

-

Dispense 5 parts 5:1 Epoxy Resin and 1 part 5:1 Slow Hardener into a clean mixing cup, and stir thoroughly.

-

If desired, pour mixed, unthickened epoxy into a small, clean, disposable plastic beaker or cup. Doing so can make it easier to dip a small brush in to wet out the fiberglass patches.

-

-

-

To repair the fiberglass, you will fill the damaged area with successively smaller pieces of fiberglass cloth, one ply at a time, wetting out each one with the mixed, unthickened epoxy.

-

The idea is to go from larger to smaller plies, in increments. The first ply should cover the repair area completely, the second ply should be a little smaller, and so on, until you have enough plies for a thick enough patch to complete the repair.

-

Start by making a template for the first piece of fiberglass, then use fiberglass shears to cut successively smaller pieces, until you have enough for your patch.

-

-

-

Use a small brush (e.g., an acid brush) to apply a thin layer of the mixed, thickened epoxy to the repair area. This epoxy layer will fill cracks/voids and create a bond for the pieces of the fiberglass patch.

-

Why is it important to use a thin layer of mixed epoxy here? Because extra epoxy becomes waste and does not add strength.

-

-

-

There are two ways to create a fiberglass patch. The first method is to build the patch, ply by ply, directly on the repair area. The second method is to build the entire fiberglass patch on a separate work area, wetting out the fiberglass between each layer, then transferring the patch to the repair area.

-

In this example, we’ll build the fiberglass patch directly on the repair area.

-

Lay down the largest piece of fiberglass and press it gently into the thickened epoxy you applied in the previous step. Use a small brush to wet out this first layer. Apply only enough mixed epoxy to saturate the cloth.

-

IMPORTANT: Extra resin will not add bulk or strength, but will create brittleness. Strength comes from the fiberglass fabric, not the resin.

-

-

-

Apply each successive piece of fiberglass, one at a time, wetting out each piece as you go.

-

It’s important to apply only enough mixed epoxy to saturate the cloth. Cured epoxy is very hard to sand, so you don’t want a thick buildup.

-

-

-

Peel ply, or ‘release fabric’, is a synthetic cloth placed on an epoxied surface immediately after the final coat of epoxy is applied. After curing, the peel ply is removed, leaving no messy amine blush to wash off of the surface. Blush is a waxy byproduct of cured epoxy, and must be removed before reapplying a product with itself or overcoating.

-

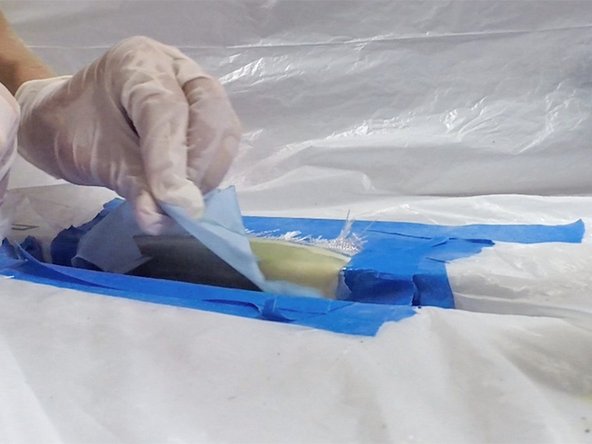

Cut and position peel ply: Cut a piece of peel ply large enough to cover the repair area, and lay it on top of the final coat of epoxy.

-

(Optional) If you have a small dry brush available, you can use it to help the peel ply stick to the epoxy completely (see second image).

-

Wet out peel ply: Use a small brush to apply a coat of mixed, unthickened epoxy on top of the peel ply fabric to prevent air bubbles.

-

Be sure not to put too much epoxy on top of the peel ply - just add a thin layer. Too much epoxy will make the peel ply harder to remove.

-

-

-

Remove peel ply: When the repair area cures completely, remove the peel ply slowly and carefully. Removing the peel ply also removes any amine blush and some of the excess epoxy.

-

Sand and/or grind: Sand/grind to shape and smooth the repair.

-

Remove residue: Vacuum to remove sanding dust.

-

Overcoat: Overcoat the repair, as desired. If the repair is not cosmetic, paint, or prime and paint.

-

For a cosmetic finish, fair the repair before overcoating. For fairing, you can apply a mixture of TotalBoat 5:1 epoxy resin]/5:1 slow hardener mixed with microballoons (to a peanut butter consistency), allow to cure, sand, clean, and apply your desired finish according to the manufacturer’s directions.

-

An easier fairing alternative is to use prethickened TotalBoat TotalFair epoxy fairing compound, then prime and paint.

-

IMPORTANT NOTE FOR OVERCOATING WITH GELCOAT:

-

In general, gelcoat is not compatible with cured epoxy. However, if the repair is small, perfectly executed, and cosmetic in nature, you can overcoat it with gelcoat. Otherwise, use an epoxy tie-coat primer such as TotalBoat TotalProtect barrier coat or TotalBoat 2-Part Epoxy Primer over the cured epoxy repair, before applying gelcoat.

-

-

-

The epoxy resin & hardener, fillers, solvents, and fiberglass reinforcement fabric used in this project contain hazardous fumes and fibers. It's important to wear the proper personal protective equipment (PPE), which will vary based on the job at hand and the products used.

-

Before you begin any project, we recommend the following:

-

Carefully read the safety information on all product labels.

-

Review the information in the SDS (Safety Data Sheets) for each product, including Section 8: Exposure Controls/Personal Protection.

-

Gather the proper PPE items, as stated by the manufacturers. Items can include, but are not limited to, the following:

-

Proper respirators for product application and for sanding cured material.

-

Suitable gloves to protect your hands, and proper eye, face, skin, and clothing protection.

-

What is epoxy sensitization? Ever heard of someone getting a skin rash after using epoxy? A rash is one form of sensitization; it's the process where your body gets more and more sensitive to epoxy products. Rashes are a common sign, but eyes, nose, throat, & lungs can also be affected. Everyone reacts differently, so proper PPE is critical.

-