Introduction

A topside paint is any paint you apply above the waterline — anywhere on your boat, including the hull, deck, and bilge. A new paint job not only makes your boat look great, it protects the surface and makes it easier to clean. Tackling topside painting yourself can give you a professional-grade finish at a fraction of what the boatyard charges—but you have to approach it the way the boatyard does. That is, about 90% of the work goes into preparing the surface. Get that right, and the painting part is easy.

Which topside paint should I use?

We offer a variety of one-part topside paints that are easy for do-it-yourselfers to apply and maintain. For safer decks that are easier to keep clean, we recommend our TotalBoat TotalTread Non-Skid Deck Paint (see How to Paint a Non-Skid Deck). While non-skid coatings are grouped under topside paints, they’re not used on hulls and are usually applied only on decks and other areas where traction is important. For bilge and locker areas, we recommend TotalBoat TotalBilge epoxy bilge paint (see How to Paint Your Boat’s Bilge). And for hulls, we recommend our high-solids TotalBoat Wet Edge Topside Paint.

Wet Edge is a high-gloss, one-part polyurethane topside finish with advanced UV stabilizers for a beautiful, long-lasting finish that won't fade, and that’s almost as glossy as two-part polyurethanes. It has excellent stain and abrasion resistance, durability, and flexibility. It’s also easy to apply by brushing, rolling & tipping, or spraying, and comes in 21 popular colors ranging from the more common ones to vivid hues with maximum color and gloss retention. If you prefer a flat, low-sheen finish, Wet Edge also comes in flat black, flat gray, and flat white.

IMPORTANT: TotalBoat Wet Edge Topside Paint can being applied to the bottom of a boat (as shown in the video below), but Wet Edge is not intended for continuous submersion on boat bottoms that remain in the water for longer than 72 hours.

Tools

Video Overview

-

-

Before you start painting, it's important to start with a surface that's clean and free of dust, dirt, wax, oil, grease, surface blush, or other contaminants.

-

Fiberglass: Wipe the surface with a lint-free rag dampened with TotalBoat Dewaxer & Surface Prep. Abrade the surface lightly with a Scotch-Brite™ pad, then wipe the surface with TotalBoat Special Brushing Thinner 100. You can now mask (Step 3) and apply Wet Edge (Step 8) directly onto the fiberglass - no priming is necessary.

-

Wood: Sand the surface smooth down to 220-grit sandpaper, then wipe clean with TotalBoat Special Brushing Thinner 100.

-

Previously Painted Surfaces: If coating is in bad condition, remove with TotalBoat TotalStrip, as directed, or use a scraper. Wipe the surface clean with TotalBoat Special Brushing Thinner 100.

-

Aluminum and Steel: See Priming (Step 6).

-

-

-

Apply a quick-release masking tape to protect adjacent surfaces.

-

-

-

Mix equal parts TotalBoat TotalFair epoxy fairing compound, as directed. Mix thoroughly until the compound is a solid green color, with no swirl marks.

-

Use a putty knife or spreader to apply mixed TotalFair to fill small dings and gouges. Before sanding, allow to dry completely.

-

-

-

Sand TotalFair. We recommended sanding TotalFair as soon as it's cured enough to sand. If TotalFair is allowed to sit more than two days, it can become harder to sand.

-

-

-

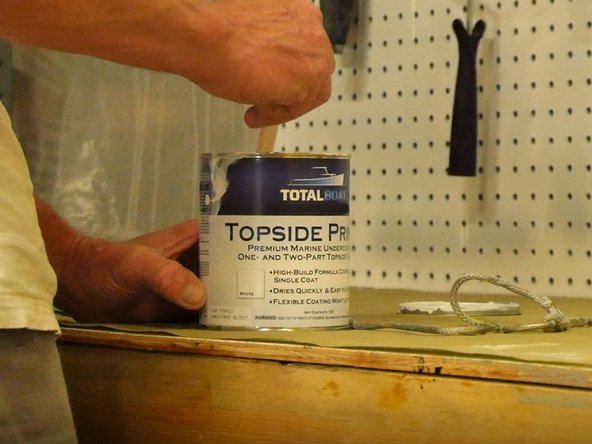

Wood and Previously Painted Surfaces: Prime the properly prepared surface with a thin coat of TotalBoat Topside Primer, as directed.

-

Aluminum and Steel: Prime the surface with TotalBoat 2-Part Epoxy Primer, as directed. Allow to cure 4-24 hours, depending on ambient temperature.

-

-

-

Wood, Previously Painted Surfaces, Aluminum and Steel: Sand the primed surface lightly with 220-grit sandpaper.

-

Do not sand through the primer; sand just enough to remove high spots and give the topside paint a good surface to stick to.

-

Wipe the surface clean with a lint-free rag dampened with TotalBoat Special Brushing Thinner 100.

-

-

-

Rolling & tipping means to apply paint with a roller (use a 1/8" nap solvent-safe foam roller cover), then follow immediately with a brush–and a light touch–to smooth out the paint. This ensures the paint is applied evenly, achieving high-gloss results, with no roller or brush marks, similar to spraying. It’s also faster than brushing.

-

For more on rolling & tipping, see the Video Overview at the beginning of this project guide.

-

Thinning: When brushing, or rolling & Tipping, you can thin Wet Edge up to 5-10% (by volume) with TotalBoat Special Brushing Thinner 100. When spraying, thin with xylene, typically, 15-20%. NOTE: The % varies by sprayer and conditions, and could be slightly higher than 20%.

-

Apply THIN coats of Wet Edge. If coats are too thick, Wet Edge will not dry properly. Film thickness per coat is 3 mils wet. That's about the thickness of 3 sheets of paper, so think THIN.

-

Application temperature range: 50-90°F, relative humidity: 0-90%.

-

Dry Time to Overcoat: 8 hrs. @ 90°F; 12 hrs. @ 70°F; 16 hrs. @50°F.

-

You will apply 2-3 thin coats, total, sanding between coats. Do not attempt to overcoat until the paint has dried to a sandable state.

-

Sand lightly between coats with 220-grit sandpaper, and wipe the surface clean with TotalBoat Special Brushing Thinner 100 before applying the next coat.

-

-

-

When working with the topside paint, primer, thinners, solvents, and other products used in this project, it's important to wear proper personal protective equipment (PPE).

-

Before you begin, we recommend the following:

-

Review the information in the SDS (safety data sheets) for each product, including Section 8: Exposure Controls/Personal Protection.

-

Gather the proper PPE, as listed by the product manufacturers, for example, suitable gloves and proper protection for skin, lungs, eyes, and clothing.

-

-

-

Wet Edge did not dry properly: Improper application thickness - The recommended application thickness is 3 mils wet (1-2 mils dry). If paint is applied too thick, the paint can surface-cure, trapping solvents & wet paint underneath. In most cases, the paint will still dry in a few days. Don't overcoat unless the surface is completely dry.

-

Wet Edge is not as glossy as it should be: Dew settled on the paint before it was fully tacked over - Do not apply Wet Edge later in the day or evening when dew may be settling, or rain or fog are present before the surface is fully tacked over.

-

Wet Edge has air bubbles in the surface: Paint was not tipped properly - When rolling & tipping, roll against the grain if possible, and immediately after, tip with a decent quality bristle paint brush in the direction of the grain. This technique takes a little time to master, and can be easier if one person rolls and one person tips.

-

Wet Edge is too glossy: Add a flattening agent - Only use flattening agents that are specified for one-part finishes. Interlux, Pettit, and Epifanes make flattening agents compatible with Wet Edge. For best results, apply the first 1-2 coats of Wet Edge without the flattening agent, and add the agent for the finish coat(s).

-